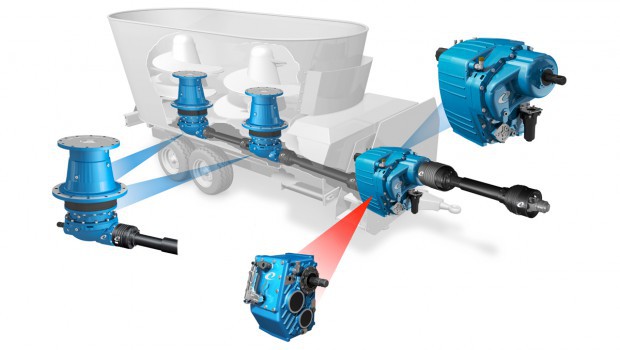

Specific solutions for food mixers will be on display. In the forage harvesting and distributing machinery sector, the manufacturer proposes transmission systems for feed mixers with vertical or horizontal augers, both stationary for feeding or biogas, as well as self-propelled or truck mounted.

PUBLICITÉ

For trailed vertical mixers, the PGA-2500 planetary drive series will also be presented, with a new output design, which reduces the overall weight and reduces the amount of lubricant. The professional range of exposed VP universal joints includes the VP6, VP8, VP9 and CVJ-VP7 series with constant velocity joint.

Comer Industries will also present its system for self-propelled feed mixers, including the category 3 S-328 axle, with exceptional load and torque capacity (12 tons of dynamic load and 58,000 Nm of maximum torque) and the gearbox Planetary PGA-2103 VM to transmit vertical drive to the auger. The PGA-2103 VM (nominal transmissible torque of 21,000 Nm and 48,000 Nm of maximum torque) is equipped with a patent pending system capable of supporting higher thermic power for heavy applications. The PGR-1702-W wheel drive will be demonstrated, ideal for sprayer machines, thanks to the large load capacity of the main tapered roller bearings and the optional wet disk dynamic brake, which can function as a brake Parking and emergency brake.

Finally, Comer Industries will showcase its professional line of VP series transmission, which includes a new CE-certified protector, high performance and easy maintenance. This range of professional products is versatile and available for many applications; The transmissions are characterized by an increased efficiency and a better respect of the environment, thanks to a reduced maintenance and a lower use of lubricants. To cover all the needs of intensive users, five models are available in the standard version with single seal and two in the constant velocity version.

The CVJ homokinetic version has a new protection system which allows operation with working angles of 80 ° without causing a collision with the cradle of the tractor. The new CVJ constant velocity joint system ensures excellent sealing, reducing pollution and maintenance intervals. Safety devices such as torque limiters and easy connection system are available. They are designed and manufactured according to quality procedures in accordance with international standards.